Ibhotile yeglasi ezenzekelayo/ ibhotile yePlastiki/ ingakwazi ukugcwalisa umatshini wejusi oshushu

Inkcazo

Ngelixa uzama ukwenza iziselo ezikhethekileyo, ezisulungekisiweyo zabathengi bakho, izixhobo zakho zebhotile kufuneka zigcine inqanaba elifanayo lokuchaneka kunye nobugcisa.Umatshini wokuzalisa uthotho lwe-JH-HF lolona khetho lulungileyo kwi-PET kunye nebhotile yeglasi eshushu yokuzalisa iimveliso zasimahla zomphunga.Ingasetyenziselwa ukuzalisa ijusi, incindi, iziselo ezibandayo, iti kunye nezinye iziselo.Ukuthengiswa kwezi ziselo kukhula ngokukhawuleza, kwaye zimele indlela yokuphila enempilo eqhutywa kukufudukela ezidolophini kunye neziseko zokuthengisa eziphuculweyo.Nokuba uluphi uhlobo lwesiselo onaso, sinokukunceda ukupakisha amaphupha akho ngobuchule bethu bobugcisa kunye nobuchule bokupakisha obuphezulu.

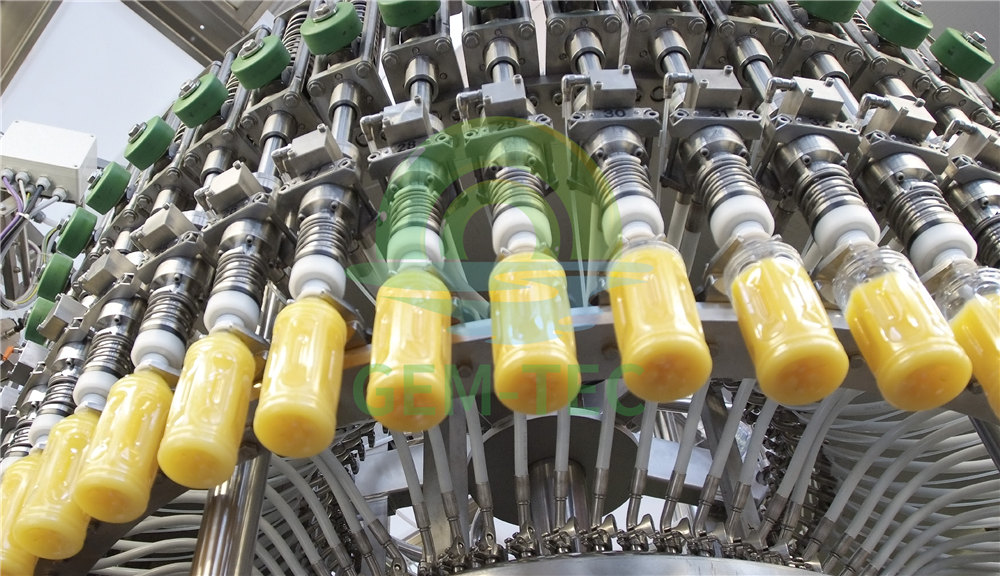

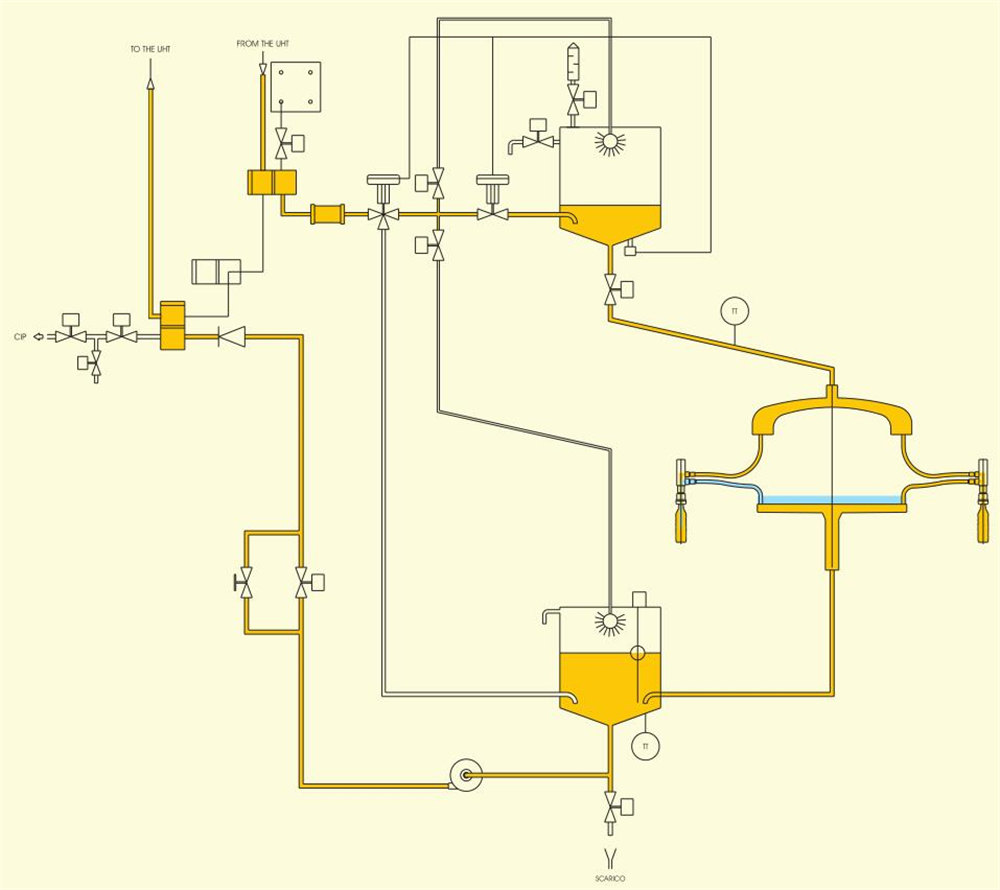

Itekhnoloji yokuzalisa i-hot imele isisombululo sokuzalisa iziselo ezimileyo ngaphandle kokongezwa kwezigcini ezifana ne-pulp yeziqhamo okanye i-fiber.Iimveliso ezishushu kwiqondo lokushisa eliphezulu (ukuya kwi-92-95 ° C, kuxhomekeke kwinkcazo yemveliso) zigcinwa kwiqondo lokushisa eliphezulu kunye ne-sterilized state ukusuka kwi-pasteurizer ukuya kumatshini wokuzalisa ukuze kuqinisekiswe ubomi obufunwayo.Inkqubo yokuzalisa i-thermal ixhotyiswe ngomsebenzi wokubuyisela kwakhona ukuqinisekisa ukuba imveliso iyinyumba ngamaxesha onke.Xa umatshini uyeka ukusebenza, ukujikelezwa kwemveliso kuqala, ukugcina ubushushu be-valve yokuzalisa rhoqo.Ukuphindaphinda kuphela kwiimveliso ezibekwe kwi-valve yokuzalisa, kungekhona kwiimveliso zebhotile.Ngexesha lokuzaliswa, i-valve yokuzalisa ihamba ngokuqhagamshelana nebhotile.Ibhotile edibana nevalve ivula ivalve ngaphandle kokuphinda kujikelezwe imveliso.Umoya ovela kwibhotile ukhutshwa nge-tube yokubuyisela imveliso.Emva kokuba inqanaba lokuzaliswa lifikeleleke, ukubuyiswa kwemveliso kuqala kwakhona.Emva koko i-valve ye-pneumatic ivala intloko yokuzalisa kwaye imise ukuphindaphinda kwemveliso.Nje ukuba izaliswe kwaye igqunywe, ibhotile ingena kwitonela yeshawari ebandayo ukuze ipholiswe.

Ukuze ukwandise ukukhuselwa kwemveliso ekungcolisweni kwebhaktheriya kunye nokwandisa ukusebenza kakuhle kokucoca kwezixhobo, imveliso isasazwa ngombhobho kwi-dispenser ejikelezayo.Isiphelo esiphezulu somhambisi sidibaniswe netanki yokugcina izinto, itanki yokugcina inokwamkela izinto ezivela kumatshini wokuvala inzalo kwaye inokubuyisela izinto ezijikelezayo kwi-valve yokuzalisa kumatshini wokuvala inzalo ukuze uqhubeke nokuzalisa.Icandelo letanki licocwa ngebhola lokutshiza.Ukuhanjiswa kunye nokubuyiselwa kwemveliso ngaphakathi kwevalve yokuzalisa nayo yenzelwe ukunciphisa ukulahleka kwemveliso ekuqaleni nasekupheleni kwemveliso.Le valve yokuzalisa ekhethekileyo ayifuni ukufakwa kwendebe yobuxoki yokucoca i-CIP ngenxa yokuba kukho i-loop evaliweyo ngaphakathi kwevalve evumela ukucoca ukuba kwenziwe.Ubume bendawo yoqhagamshelwano phakathi kweendawo ezisisigxina kunye nezihambayo zenzelwe ukubonelela ngesantya esifanelekileyo sokucoca.

Iimbonakalo

Iimpawu zetekhnoloji zokuzalisa ezishushu

1. Isixhobo sinetanki yangaphandle yokondla kunye nokuhlaziya iimveliso.Xa umtshini ungenayo iibhotile, imveliso iphinda isetyenziswe: intloko yokuzalisa ihlala igcinwe kwiqondo lokushisa eliphezulu.

2. Inkqubo yokulawula i-Siemens, enekhono eliphezulu lokulawula i-automation, zonke iinxalenye zomsebenzi wokusebenza ngokuzenzekelayo, akukho msebenzi emva kokuqalisa.

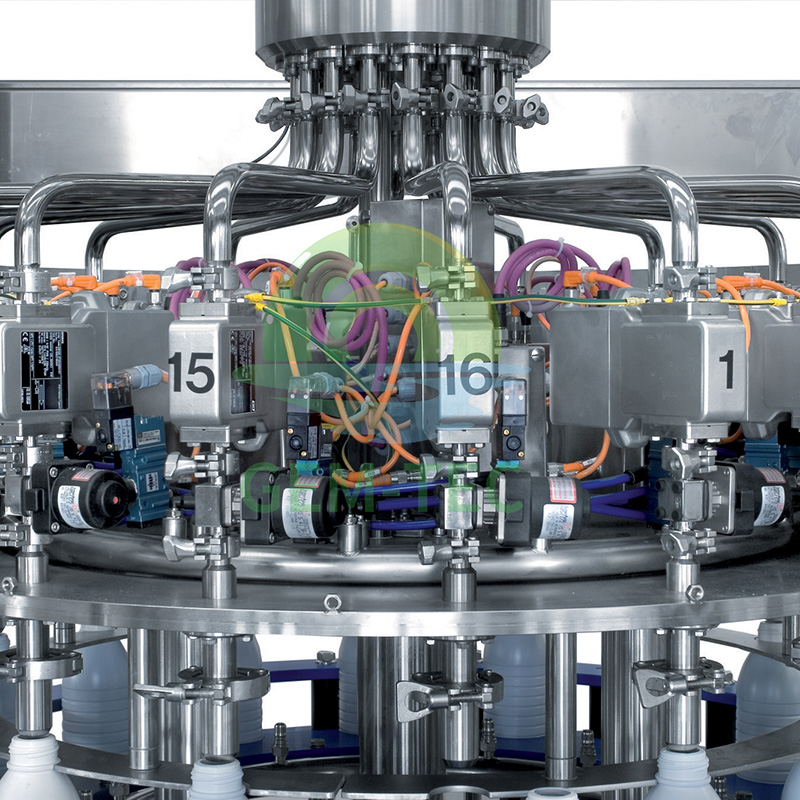

3. Ukulawulwa kwe-elektroniki kunye ne-pneumatic yazo zonke iivalve zokuzalisa, ukugcinwa lula.Ukuzaliswa okuchanekileyo komyinge wokuzalisa, uhlobo lwe-electromagnetic flowmeter volumetric filling, ivalve yokuzalisa kunye nebhotile musa ukunxibelelana ngexesha lenkqubo yokuzalisa, kunqande ukungcoliseka komnqamlezo.

4. Umjelo wezinto eziphathekayo unokucocwa i-CIP ngokupheleleyo, kwaye i-workbench kunye nenxalenye yoqhagamshelwano yebhotile inokuhlanjwa ngokuthe ngqo, ehlangabezana neemfuno zococeko zokuzaliswa;Iikomityi zomgunyathi ze-CIP ezizenzekelayo zikwakhona.

5. Ukuqinisekisa inqanaba eliphezulu lokucoceka kwinqanaba ngalinye, umatshini wakhiwe ngensimbi engenasici kwaye une-countertop ye-sloping yokunciphisa umngcipheko wokungcoliswa kwe-microbial.

6. Ulawulo oluphezulu lwe-recirculation kunye ne-actuator yangaphandle kwi-pneumatic version ye-valve ye-membrane ukulawula izinga lokuphindaphinda kwemveliso kunye nokuphepha i-spatter yemveliso.

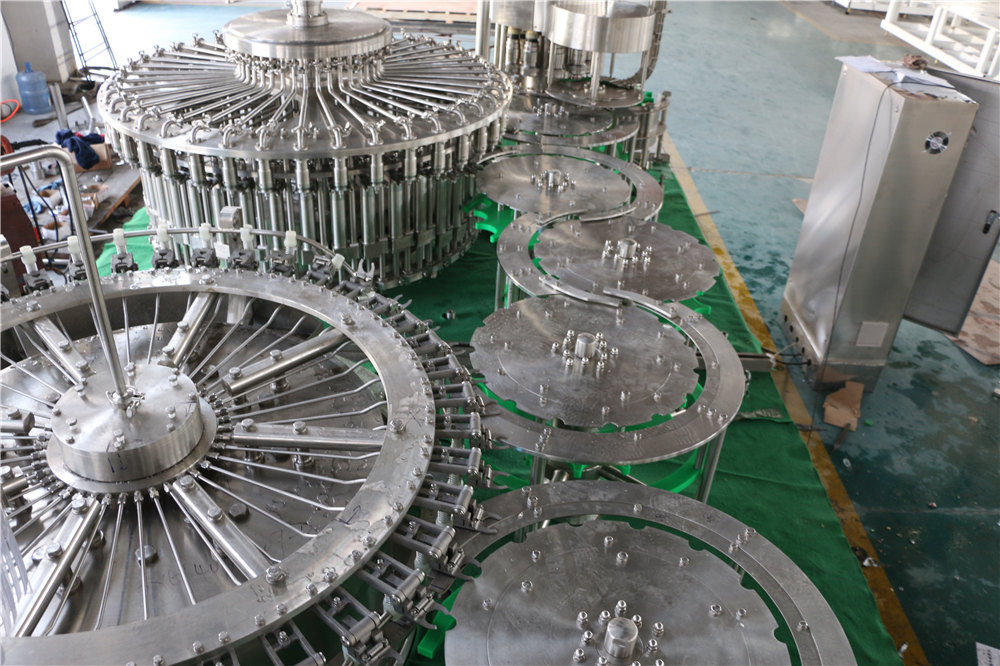

7. Ukuhanjiswa komatshini kwamkela idizayini yemodyuli, ukuguqulwa kwamatyeli okulawulwa kwesantya esingenanyathelo, uluhlu olubanzi lolawulo lwesantya.I-drive ixhotyiswe ngesixhobo sokuthambisa ngokuzenzekelayo, esinokubonelela ngeoyile kwindawo nganye yokuthambisa ngokwesidingo sexesha kunye nobungakanani, kunye nokuthambisa okwaneleyo, ukusebenza kakuhle, ingxolo ephantsi kunye nobomi benkonzo ende.

8. Iinguqulelo ezahlukeneyo zinokubonelelwa ngokweenkcukacha zabathengi.

Ulwakhiwo

Inkcazo yobuGcisa

Iimveliso ezingaphelelanga kwiParameter yoBugcisa

| Umzekelo | Ukuhlamba iintloko | Ukuzalisa iintloko | Capping iintloko | Imveliso Umthamo | Umatshini Amandla | Ubunzima | Umyinge jikelele (mm) |

| JG-HF 14-12-4 | 14 | 12 | 5 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| JG-HF 18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| JG-HF 24-24-8 | 24 | 24 | 8 | 8000B/H (500ml) | 5kw | 6500kg | 3100*2450*2300mm |

| JG-HF 32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| JG-HF 50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900 mm |