Umatshini wokuzalisa utywala weWhisky ngokuzenzekela kwibhotile yeglasi

Inkcazo

Imimoya ziziselo ezinxilisayo ezigalelwe ngaphandle kokubiliswa.Imimoya edityanisiweyo ikholisa ukuba nepesenti ephezulu yotywala ngomthamo, ukusuka malunga ne-20% ukuya kwi-90% ye-ABV.Ukwenza umoya oqinileyo, izinto eziluhlaza ezifana neziqhamo, iitapile kunye neenkozo zisetyenziselwa inkqubo yokucoca.Iziselo ezinxilisayo eziqhelekileyo yiwhiskey, igin kunye nevodka.Imakethi yesiselo esinxilisayo kwihlabathi kulindeleke ukuba ifikelele malunga ne-2 yeebhiliyoni zeedola ngo-2025, uphando lwathi.Imimoya iya kuphendula malunga nesithathu kwimarike iyonke.Okubonakalayo, imimoya yenza isabelo esikhulu semarike.

Ukuphakama kwexabiso lemveliso, ilahleko engaphezulu iya kubangela ukulinganisa okungachanekanga kokuzaliswa.Ukuze ugweme ilahleko enjalo, umatshini wokuzalisa utywala we-GEM-TEC ulandela ngokungqongqo iimfuno zenkqubo yokuzaliswa ngokuchanekileyo.Ukuba imveliso eninzi igalelwe kwisikhongozeli, inkqubo iya kuzilungisa ngokuzenzekelayo inqanaba lolwelo.Iimveliso ezinotywala obuphezulu nazo zifuna unyango olunokuqhuma kwinkqubo yokufaka iibhotile.Inkqubo yombane yomatshini wethu ithatha iimveliso ezinobungqina bokudubula ukuphelisa umngcipheko wokhuseleko olunokwenzeka.Izisombululo zethu kulula ukuzicoca ukuze iimveliso zakho zikwazi ukuhlangabezana nazo zonke iimfuno zococeko.

Umgaqo osebenzayo wokuzalisa utywala obucacileyo kwisitya seglasi

Umatshini wokuzalisa imimoya ngokubanzi wamkela indlela yokuzalisa i-vacuum.Imimoya efakwe ebhotileni ichithwa ecaleni kodonga lwangaphakathi lwebhotile ngesambrela ye-diverter, kwaye umoya osebhotileni ufunxelwa yinkqubo yokucoca ngombhobho wokubuyisela.Inkqubo ethile yile ilandelayo: ibhotile iphakanyiselwa phezulu ukuya ngaphantsi kwe-valve yokuzalisa kwaye i-valve yokuzalisa ivuliwe.Ukuzaliswa kuqala.Xa inqanaba lolwelo lwewayini ebhotileni liphezulu kunombhobho wokubuyisela, ivalve iya kuvalwa.Inqanaba le-liquid emva koko lilungiswa nge-vacuum: imveliso engaphezulu ifunxelwa kwakhona kwi-cylinder yokuzalisa ngetyhubhu emfutshane.Ngenxa yokuba umsebenzi wokuvula kunye nokuvala i-valve ulawulwa yibhotile, ngoko: "akukho bhotile, akukho nkqubo yokuzalisa".

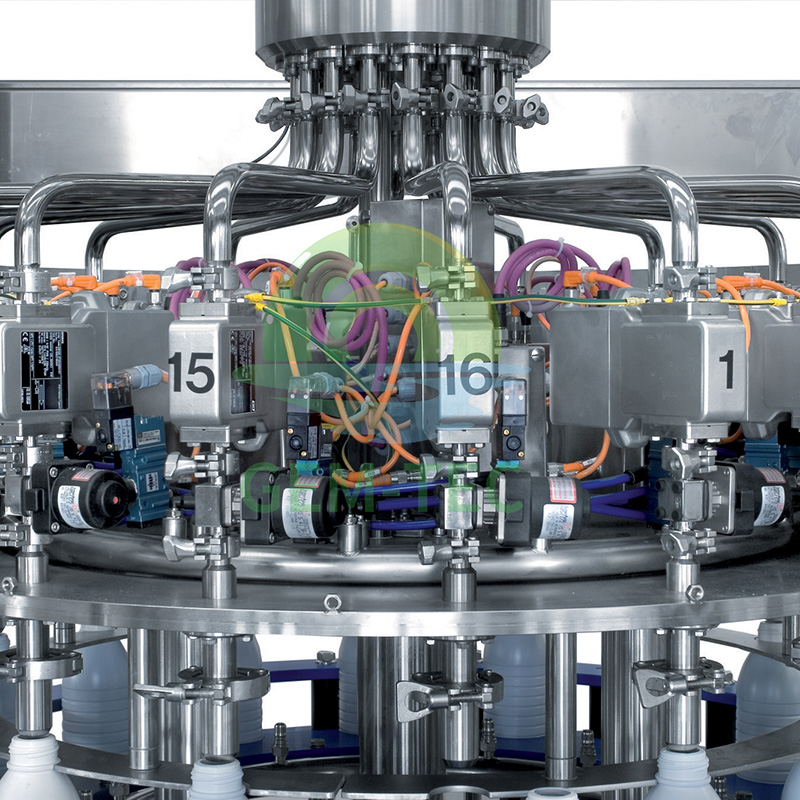

Ngokuqinisekileyo, kwi-GEM-TEC ukuzaliswa kotywala kunokusebenzisa inkqubo yokugcwalisa i-electron floating ibhola yobungakanani, ukuchaneka kokuzalisa kuphezulu, ngokukhawuleza.I-valve ye-elektroniki ithatha umlinganiselo wexesha langempela kunye neteknoloji yokulawula, iteknoloji yembuyekezo yokusebenza kwe-PLC yokulandelela kunye neteknoloji yokulawula ukuhamba okuguquguqukayo ukutyhala ukuchaneka kokuzaliswa kunye nokuzaliswa kwesantya ukuya kubude obutsha.Inkqubo yokuzaliswa iyafana nesakhiwo se-valve yeendlela ezintathu.Imimoya iqala ngokutofwa kumbhobho wemitha wombane.Emva kokufikelela kumthamo omiselweyo, imimoya kwi-barrel yokulinganisa ifakwe kwibhotile.

Iimbonakalo

Iimpawu zokusebenza kwevalve yoomatshini

1. Ukuqinisekisa amanqanaba afanelekileyo okugcwalisa iimpazamo kunye nelahleko yotywala

2. Qinisekisa ngokuchanekileyo ukuphakama kwenqanaba lokuzalisa ngokulungiswa kwe-vacuum kunye nobude bombhobho wokubuyisela

3. Ivalve yokuzalisa elawulwa ngoomatshini, inokuthi +/- 4 mm ubude obungena-stepless bokuzalisa

4. I-valve yokuzalisa i-valve kunye okanye ngaphandle komsebenzi we-CIP

5. Isingxobo sokugcina sikwimo ephantsi yevacuum, ngaphandle kokuzaliswa kwe-drip

6. Inkqubo yokulawula i-Siemens, enekhono eliphezulu lokulawula i-automation, zonke iinxalenye zomsebenzi wokusebenza okuzenzekelayo, akukho msebenzi emva kokuqaliswa.

7. Ukuhanjiswa komatshini kwamkela uyilo lwemodyuli, ukuguquguquka okuguquguqukayo kokulawulwa kwesantya esingenanyathelo, uluhlu olubanzi lwesantya.I-drive ixhotyiswe ngesixhobo sokuthambisa ngokuzenzekelayo, esinokubonelela ngeoyile kwindawo nganye yokuthambisa ngokwesidingo sexesha kunye nobungakanani, kunye nokuthambisa okwaneleyo, ukusebenza kakuhle, ingxolo ephantsi kunye nobomi benkonzo ende.

8. Ukuphakama kwezinto eziphathekayo kwi-cylinder yokuzalisa kuchongwa yi-probe ye-elektroniki.Ulawulo lwe-PLC oluvaliweyo lwe-PID luqinisekisa inqanaba lolwelo oluzinzileyo kunye nokuzaliswa okuthembekileyo.

9. Iindlela ezahlukeneyo zokutywina azikhethwa (ezifana nezi: i-aluminiyam ikepusi, ikepusi yesithsaba, idlala elimile ezahlukeneyo, njl.njl.)

10. Umjelo wezinto eziphathekayo unokucocwa i-CIP ngokupheleleyo, kwaye i-workbench kunye nenxalenye yoqhagamshelwano yebhotile inokuhlanjwa ngokuthe ngqo, ehlangabezana neemfuno zococeko zokuzaliswa;Ingasetyenziswa ngokwemfuno yetafile ethambekele kwicala elinye;Iikomityi zomgunyathi ze-CIP ezizenzekelayo zikwakhona.

Ukongeza kwezi mpawu zingentla, ivalve yombane inezi mpawu zilandelayo:

● Akukho lahleko, kulula ukuyilungisa: ibhotile kwinkqubo yokuzalisa ngaphandle kokuphakamisa ukunyakaza, ayiqhagamshelani nomzimba we-valve, phantse akukho nxalenye yokugqoka;Xa ulungelelanisa umthamo, kufuneka ucofe kuphela isikrini sokuchukumisa ukuze utshintshe iiparitha ukwenza uhlengahlengiso olungenanyathelo, kwaye unokugcina iiparitha zeentlobo ezahlukeneyo zewayini kwinkqubo yefomula.Xa utshintsha iwayini, kufuneka ubize kuphela iindidi kwisikrini sokuchukumisa ukuze ugcwalise ngokuzenzekelayo, uphucule kakhulu ukusebenza kwemveliso.

● Uqwalaselo oluphezulu, ukuthembeka okuphezulu: xa kuthelekiswa nenkqubo ye-valve yomatshini, amacandelo amaninzi e-elektroniki athatha inxaxheba kwinkqubo yokuzaliswa, ulawulo lwenkqubo luchaneke ngakumbi, ukufumanisa okubuhlungu ngakumbi.

● Akukho manzi okukhangayo, akukho dripping: i-valve yokuzalisa ithatha i-channel ye-damping, utywala akulula ukukhupha i-bubble, kufuphi nomlomo webhotile xa izinga lokuhamba kwamanzi liyancipha, ikholomu yolwelo iya kuba bhetele kwaye ifakwe ngokukhawuleza kwibhotile, isuse ulwelo. igwebu, ukutywinwa okubuyela umva emva kokuzaliswa, akukho kuthontsiza.

IParameter yobuGcisa

| Uhlobo lomatshini | fillinghead | Ukuphakama kwebhotile | Idayamitha yebhotile | Ukuphumelela kwemveliso | Ukuzalisa ukuchaneka | Ukuzalisa uluhlu | Uxinzelelo lomoya ocinezelweyo |

| JH-FF18 | 18 | 100-300 | 50-100 | ≤6600(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 24 | 24 | 100-300 | 50-100 | ≤9000(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 36 | 36 | 100-300 | 50-100 | ≤14000(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 48 | 48 | 100-300 | 50-100 | ≤18000(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 60 | 60 | 100-300 | 50-100 | ≤22000(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |

| JH-FF 72 | 72 | 100-300 | 50-100 | ≤26000(b/h) | ±1.0ml/500ml | 40-600ml | 0.4-0.5MPa |