Ibhokisi yebhokisi yeRobhothi ezenzekelayo / iPalletizer yokuSonga iShrink

Ividiyo

Inkcazo

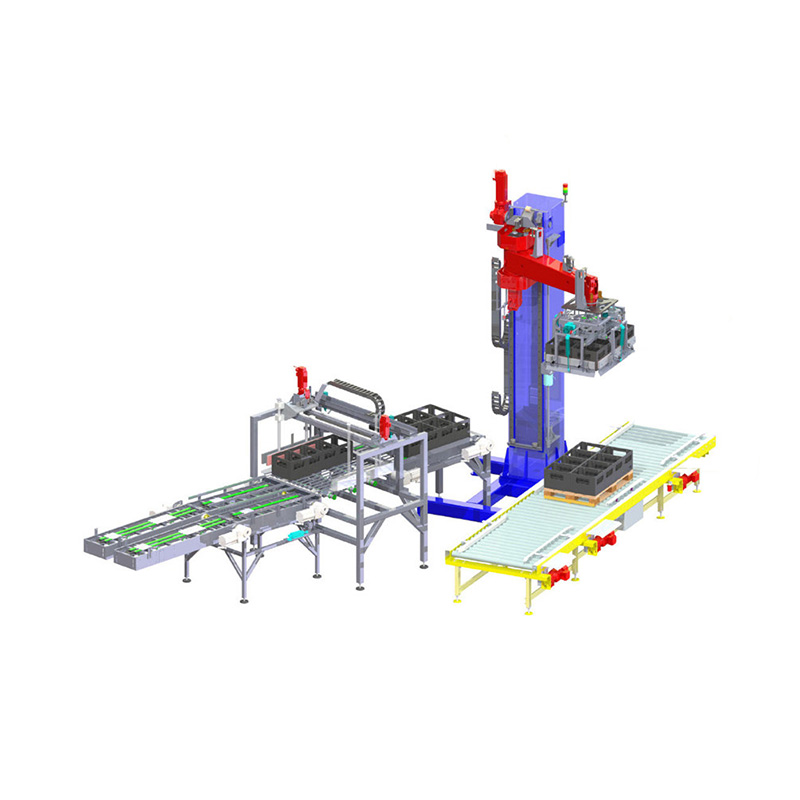

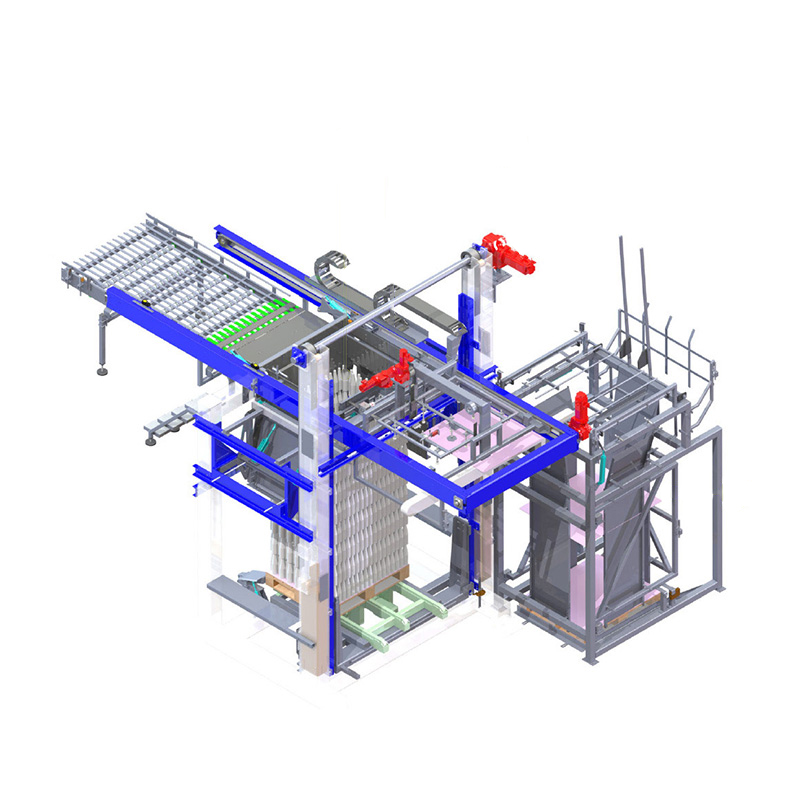

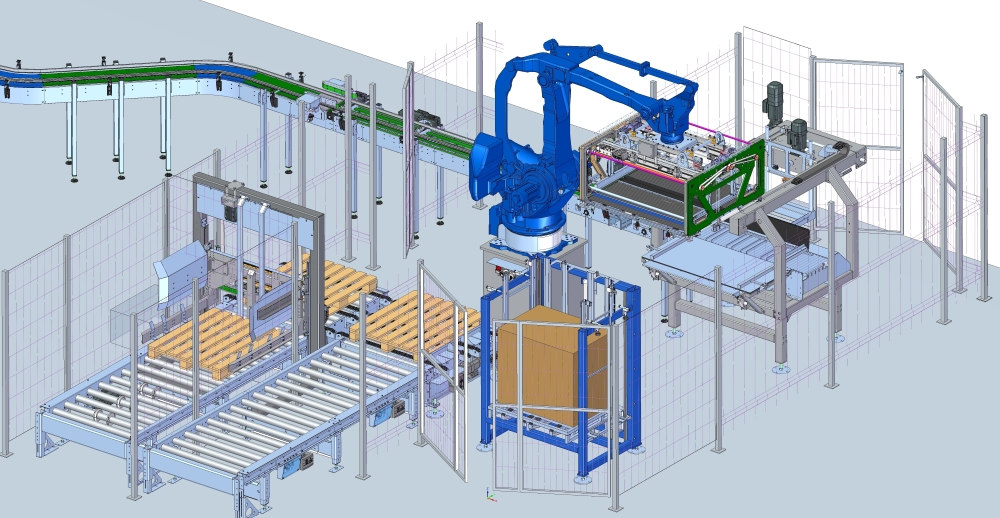

I-Robot palletizer yimveliso ilayishwe kwibhokisi, ibhokisi ye-turnover, iingxowa kunye neminye imithetho yemveliso, ngomgca wokuhambisa uya kulungiswa kwaye ubekwe;I-10-12 iipaliti ezibekwe ngokucocekileyo zibekwe kumatshini we-pallet ozenzekelayo nge-forklift, kwaye umatshini uyahlula ngokuzenzekelayo iipaliti ngokulandelelana kwaye uzithumele kwindawo yokubeka i-palleting kunye ne-palleting.I-robot iya kubamba imveliso ngokusebenzisa i-fixture ekhethekileyo, kwaye ngokuhambelana nokubekwa kwangaphambili kwi-pallet, umgca wokuhambisa i-pallet uqala emva kokugqitywa kwezixhobo zokukhupha i-palletizing pallet, nge-forklift fork ukukhupha umgca.Yonke le nkqubo igqitywa ngokuzenzekelayo ngaphandle kokungenelela komntu.Ilungele ukusetyenziswa komgca wendibano, inokunciphisa kakhulu ukusebenza kunye nokunciphisa amandla okusebenza.Yamkela ingqikelelo yesantya esiphezulu, uzinzile kunye noyilo lokugcina indawo, ngokukhawuleza kunye nokonga indawo.Umatshini omnye oneenjongo ezininzi, uhlengahlengiso olukhawulezayo, akufuneki utshintshe iimveliso ezipakishweyo kunye nexhala.

Ubungakanani besicelo: ikhathoni ekalisiweyo, ibhokisi yeplastiki, ukupakishwa kwebhakethi, ukupakishwa kwengxowa, njl.

Ukubunjwa kwezixhobo: umgca wokuhambisa imveliso, umgca wokumisa umgca, i-robot palletizing, isiseko, ukulungiswa, umatshini wokusabalalisa i-pallet, i-pallet yokuhambisa umgca, inkqubo yokulawula umbane kunye nenetha yokukhusela ukhuseleko, njl.

Iimbonakalo

1. Ukusetyenziswa kwe-ABB okanye i-KUKA okanye i-yaskawa stacking robots, ukuqinisekisa ukuba indawo yokubeka i-stacking ichanekile kwaye izinzile.

2. Unokusetwa kwangaphambili kwiinkqubo ezahlukeneyo ze-palletizing, utshintsho lwenkcazo lunokubizwa nangaliphi na ixesha kwisikrini sokuchukumisa, ngaphandle kokutshintsha iindawo.

3. Ukusetyenziswa okuguquguqukayo, i-robot inokuhambelana ne-1-4 imilinganiselo eyahlukeneyo yeemveliso ngexesha elifanayo le-palletizing, ukuhambelana okunamandla.

4. Umthamo welayibrari ye-pallet mkhulu, unokuthatha i-10-12 i-pallet engenanto, inokuqonda ukunikezelwa ngokuzenzekelayo kwe-pallet.

5. Ukusetyenziswa kwamacandelo ombane odidi lokuqala lwamazwe ngamazwe, ukumisela ukuzinza kwezixhobo.

6. Icocekile, intle kwaye isebenza kakuhle;Inokunciphisa kakhulu umsebenzi.

7. Ukusebenza kwesikrini sokuchukumisa ukufezekisa i-dialogue yomatshini wendoda, kunokubonisa isantya sokuvelisa, imbangela yephutha kunye nendawo, iqondo eliphezulu lokuzenzekelayo.

8. I-PLC inokucwangciswa ukulawula inani lee-stacking layers, i-pallet supply kunye nokukhutshwa kweekhathoni.

9. Inkqubo yokulawula: ukulawula isikrini sokuthintela, kunye nencwadana, imodi yokusebenza ngokuzenzekelayo, isikrini sokuchukumisa kunye nomsebenzi wonke wokusebenza komatshini.

10. Ukujongwa kwexesha langempela kuyo yonke inkqubo yokusebenza kwezixhobo.Onke amanyathelo asebenzayo afunyanwa ngababonisi abanomsebenzi wokuzixilonga.Xa kukho nayiphi na impazamo eyenzekayo, izixhobo ziya kumisa ngokuzenzekelayo, ukukhanya kwe-alamu kuya kukhanya, kwaye uhlobo lwephutha luya kuboniswa kwisikrini sokusebenza.

11. Ikhabhinethi yokulawula umbane ozimeleyo, ibhokisi yokulawula kunye nefeni yokupholisa, i-socket fluorescent.

12. Umgca wonke unikezelwa nge-slot yocingo, kwaye i-outlet slot ikhuselwe ngumbhobho.

13. Iintambo ziphawulwe ngeenombolo zomgca, kwaye iitheminali zinqanyuliwe.

14. Izixhobo zokwenza intshukumo ebuyelanayo yentambo kusetyenziswa irobhothi intambo ekhethekileyo ebhetyebhetye.

Umatshini wonke uxhotyiswe ngomnyango wokhuseleko, xa umnyango uvuliwe, umatshini uyayeka ukusebenza ukuqinisekisa ukhuseleko lwabasebenzi.

IParameter yobuGcisa

| Uhlobo | XYMD-12/R |

| Umthombo wamandla | 380V 50HZ 20Kw |

| Imveliso esebenzayo | Iikhathoni, iibhokisi zentengiso, iibhegi, iimveliso ezinemivalo, njl |

| Ubungakanani bemveliso | Lungiselela njengoko kufuneka |

| Ubungakanani bepallet esebenzayo | L1000 ~ 1200 * W1000 ~ 1200 * H120 ~ 150mm(Ngokoyilo loyilo lwepallet) |

| Imo yolungiselelo | Lungiselela njengoko kufuneka |

| Ukupakisha ukuphakama | ≤1800mm (Ukhetho lwerobhothi lunokwenziwa ngokweemfuno) |

| Isantya | I-10-12 ibetha ngomzuzu (Ngokokubekwa kohlobo lwesitaki kunokuba ngaphezulu kokubambisa) |

| Uxinzelelo lomoya | ≥6 Kg/cm² |

| Ukusetyenziswa kwegesi | 0.2m³/mz |

| Ubude bothutho lwemveliso | 900mm(Yenza ngokwezifiso njengoko kufuneka) |

| Iphalethi ehambisa ukuphakama | 600mm(Yenza ngokwezifiso njengoko kufuneka) |

| Indlela yothutho yePallet | Ngokwesakhiwo se-pallet singasetyenziselwa uhlobo lwegubhu, uhlobo lwekhonkco, ipleyiti yekhonkco, njl |

| Ukuncipha komatshini | Ngokoyilo olululo |

| Ubunzima bomatshini | 2000Kg |

| Imathiriyeli yezixhobo | Eyona nto iphambili yi-carbon steel yokutshiza iplastiki, kwaye inxalenye ekudibaneni nayo yintsimbi engenasici (Yenza njengoko kufuneka) |

| Ubumbeko lwesixhobo | (Yenza njengoko kufuneka) |